- Joined

- Dec 8, 2023

- Messages

- 362

- Location

- Houston & SE Wisconsin

- Display Name

Display name:

StraightnLevel

...

Last edited:

Unfortunately, there is no one answer as there are a number of variables that influence the numbers. For example, geographic location and even what is your definition of "restoration" vs refurbishment can cause huge swings in costs. From a maintenance standpoint, what I would recommend to potential owners when buying their 1st aircraft or 10th aircraft, is to set your budget and determine what you want for that money.Trouble is, I don't really know how to price the restoration work to get an idea of what the all-in, ready-to-fly investment would be. How do you compare a fully-restored example from one that is airworthy, but looks like it hasn't been touched in my lifetime?

$20K and up. Quality, complexity, size of aircraft and labor rates.…

What does it generally cost to re-paint a small GA aircraft? What drives that price up or down?

$10K & up depending on upholstery choices, side panels, etc., and any corrosion repair found when all the panels are removed. Labor rates.…

What about interior? To do a full restoration, i.e., carpet, seats, interior panels? What are the price drivers here?

Dual dynon w/AP, $30k & up before labor. Does not include a navigator.…

What about a full re-instrument job? I think I know what a couple of G5s would cost, but how much is it if you're pulling out original steam gauges and going full glass, say a G1000?

If its done right, it has to be completely stripped

The thing about P&I and avionics is usually also likely add weight to the plane. Might only be 10lbs, might be more. That eats into useful load.…

For example, if I find something that is absolutely perfect except that the paint is 40 years old and looks 50, I would likely buy it and deal with the painting cost. Same for an interior...

You might rethink the engine part (if I understood you to mean you’d shy away from an airplane needing an engine). There’s pluses and minuses to everything as usual, but I’d strongly consider buying an airplane with great paint, interior, and especially avionics, but with a runout engine. The reason is that you will pay a significant premium on a low or mid-time engine. However, depending on how that engine was (or wasn’t) taken care of, you may get a full life from it, no life from it, or anything in between. If it craps out 25 hours in, you’ll now be paying for an overhaul and the premium you paid for the “low time” engine is wasted.It's not so much about saving money as much as finding the right sort of plane and understanding what I'm willing to deal with vs. must-haves at time of purchase.

For example, if I find something that is absolutely perfect except that the paint is 40 years old and looks 50, I would likely buy it and deal with the painting cost. Same for an interior. Engine? Probably not (knowing that this is an area of rolling the dice every time you fire it up).

It's helpful to have an idea of what things cost so that I don't get into a project that leaves me both broke and grounded at the same time.

Yes indeed. Here’s a pic of a lower instrument panel that I finished a few months ago. Converted an original multi piece degraded plastic overlay to a one piece metal lower with new switches, breakers, engine controls, environmental controls, etc. Cost about $2,500 in parts. Labor on the other hand was excessive. I’m ashamed to say it took close to 100 hours. Keep in mind I’m a one man show. Lots of research, paperwork, multiple trips to the airport, supply orders, back and forth with drawings, reworking dimensions, laser engraving, fitting, wiring, rigging, and the list goes on.When considering the cost of avionics, don’t forget the substantial cost of installation labor, particularly if you are doing full-panel upgrades like glass, AP, etc.

That is beautiful. And the kind of thing you can only do yourself and eat the labor.Yes indeed. Here’s a pic of a lower instrument panel that I finished a few months ago. Converted an original multi piece degraded plastic overlay to a one piece metal lower with new switches, breakers, engine controls, environmental controls, etc. Cost about $2,500 in parts. Labor on the other hand was excessive. I’m ashamed to say it took close to 100 hours. Keep in mind I’m a one man show. Lots of research, paperwork, multiple trips to the airport, supply orders, back and forth with drawings, reworking dimensions, laser engraving, fitting, wiring, rigging, and the list goes on.

How much interior work can you do yourself in a certified plane? What requires A&P signoff? For example, the lower panel shown above - can you do things like that without having to pay a shop, or is the panel off-limits even if you don't touch the actual avionics, wiring, etc.?My local FBO quoted me about $12,000 to do my Mooney interior using AirTex carpet and seat kits. This would include repair and painting of the plastic parts.

A full deal interior, meaning covering all the plastic parts with Ultra Leather, custom carpets and seat upholstery and leather covered yokes and nice embroidery can run over $25,000 plus removal and reinstall.

You can also price the AirTex stuff and do it yourself.

Everything as listed in Part 43 Appx A(c) and further defined as preventive maintenance in Part 1. However, there are limits such as items requiring removal/disassembly of primary structure or operating systems, altering the basic interior layout, etc.How much interior work can you do yourself in a certified plane?

Removal/disassembly of primary structure or operating systems, alterations to the basic interior design, empty weight & balance corrections over 1 pound, etc.What requires A&P signoff?

No. That panel work above would be considered an alteration.For example, the lower panel shown above - can you do things like that without having to pay a shop, or is the panel off-limits even if you don't touch the actual avionics, wiring, etc.?

In general, aviation items are classified as “products” and “articles.” Appliances and components are a sub-set of those classifications:What constitutes an "appliance or component part" as stated in 43.3?

??? If referring to 43.3(h) & (i) that only applies to Part 135 ops.What is an "approved training program" for replacing a seat cover?

Not really. 43.3 defines who can perform the maintenance and 43 Appx A(c) lists "categories" of preventive maintenance.It seems that 43.3 and 43 Appendix A.3.(c).15 are contradictory....?

Worst case ? how much money do totally have, what airplane, what vintage, how far out from the last annual, what kind of annual was it ( a quick pencil whipping or a thorough inspection and things were fixed or deferred) are you doing the work, assuming you are qualified, are you able to put all your time in, how much of a restoration is it, do you intend more? A lot of factors /variables. probably better to approach it from the other end Figure what budget you have then find something that is likely to fit.As I'm starting to look at planes, it's clear that my budget drops me into a fairly wide range of options, and they range from flight-ready to....ahem....opportunities for improvement. Trouble is, I don't really know how to price the restoration work to get an idea of what the all-in, ready-to-fly investment would be. How do you compare a fully-restored example from one that is airworthy, but looks like it hasn't been touched in my lifetime? So:

What does it generally cost to re-paint a small GA aircraft? What drives that price up or down?

What about interior? To do a full restoration, i.e., carpet, seats, interior panels? What are the price drivers here?

What about a full re-instrument job? I think I know what a couple of G5s would cost, but how much is it if you're pulling out original steam gauges and going full glass, say a G1000? Yes, I can find the list price for the electronics and STC, but how much should I budget for a new panel and installation, worst case?

I removed many many wasp and mud dauber nests over a period of a few years meaning no one has been in there for years before I started flying it. I still don't think I have them all out yet.Airframe problems that show up when you start pulling the interior or taking the wings, off, etc., can turn into a game-changer real quick. Corrosion, cracked major components, old damage that wasn't properly repaired can all turn into a financial nightmare. Many critical parts aren't made anymore (like the Cessna spring-steel flat MLG legs, or the Cardinal wing spar carrythrough) and now you're competing with the owners of other airplanes like yours to find that stuff somewhere.

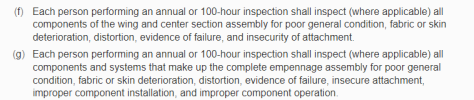

And that is due to cheap maintenance. The interior never gets pulled to get a look at the structure. Even some inspection panels or wing root fairings are never pulled off to get a good look at the highly-stressed stuff. FAR43 Appendix D outlines the MINIMUM stuff to be done at annual or 100-hour inspections, and it has stuff like this in it:

View attachment 129415

So how does one comply with that if the interior, fairings and other stuff aren't removed? Why did I find so many rusted-in screws in inspection covers, so many ancient mouse nests, so many cracked bulkheads and the like?

Beware. Unpleasant surprises are not uncommon.

Good man. I bet 90% of light airplanes never get that sort of inspection. Ever. If it's being done by the shop, it can turn into a budget-breaker for the owner, so it never gets done. The guy that buys such an airplane gets the first-annual shockers.It's PIA but I do remove the interior each year to look at what I can.

I feel good after I do it.

Look at some of the crap I found.

It might be better to do a thorough prebuy inspection, on the scale of what Gary Ward does.It might be better to go in with the plan that it's going to need a bunch of work, than to go in hoping it needs very little.

Thank you for sharing your expertise. I think I was looking at the wrong side when trying to inspect for door post cracks. Inspection needs to be done when the airframe reaches 4000 hrs I believe?View attachment 129420

At locations "A", under those plastic covers, the bulkhead tends to crack. It flexes as the rudder shoves the tail around. The big back window above that place made the fuselage too flexible there.

Locations "B" are where that bulkhead cracks at the holes cut for the bag door hinges.

Under "C" is a cluster of pulleys for the elevator, rudder and trim cables. They tend to seize up as the lube hardens in their bearings.

At the bottom of the aft doorposts, at "D," you might find cracks. Hard to see. The covers have to come off and you look forward, using a light and mirror, just inboard of the aileron cable pulleys to see the crack. There's a kit to fix it, but a pain to install.

View attachment 129422

From this useful document: https://www.cessnaflyer.org/media/kunena/attachments/1805/1969-76172SID.pdf

I would call that maintenance. Just keep at it.I have been updating? or restoring parts of this plane for 5 years now all the while keeping it airworthy so I can keep flying it with a few days here and there when it is down. Usually I do it when foul weather is forecasted.

Yea maintenance was the word I was looking for. ThanksI would call that maintenance. Just keep at it.

In my old plane, we found fuel lines that were original to the plane that were over 60 years oldYou just need to keep at it over the years.

That's the forward doorpost you're looking at. It carries the loads from the wing struts. The one in the drawing is the aft doorpost. It joins to the main landing gear box's rear bulkhead.Thank you for sharing your expertise. I think I was looking at the wrong side when trying to inspect for door post cracks. Inspection needs to be done when the airframe reaches 4000 hrs I believe?

I think a section of the floor has to be cut out to inspect that area and for the kit to be installed?