Sinistar

En-Route

- Joined

- Sep 9, 2016

- Messages

- 3,734

- Display Name

Display name:

Brad

TLDR Version:

How you do check level on a high wing Cessna? Where to place the level?

Our last annual was pretty interesting. Did a few simple updates instead of just fixing squawks. One fix was that the plane was rolling left in cruise making it hard to fly hands free. He (A&P)termed it flying "pilot side heavy" or "pilot wing heavy"...never heard that before. I was like "Do you just adjust a aileron cable or something?". He smiles "I will tilt the wing a bit more ". Okay...never knew that either. Pretty interesting how the design supports this and actually its not that much effort ($$$). He also assured me its never been adjusted since it left the factory. But the plane always had a wing leveler (until it died last winter) so maybe the other owners never cared to get it rigged properly. Even funnier...took me about 100hrs of flying to finally do something about it.

". Okay...never knew that either. Pretty interesting how the design supports this and actually its not that much effort ($$$). He also assured me its never been adjusted since it left the factory. But the plane always had a wing leveler (until it died last winter) so maybe the other owners never cared to get it rigged properly. Even funnier...took me about 100hrs of flying to finally do something about it.

So this is for a Cessna 182P, probably applies to many other planes as well.

So for the pilot wing heavy he took a guess and angled it slightly more. Now, once I reach cruise I rudder trim until the slip/skid ball is dead center. I re-trim the elevator, etc. It is still just slightly pilot wing heavy. If I use a bit more rudder trim than needed (ball is now slightly left of center) it seems even better (very, very slow roll rate). But am I now uncoordinated slightly in a way that stops the left roll rate with hands off?

So my (A&P) gave me some homework LOL! Partly because he's busy and partly because he's letting me learn something I think He asked me to get the slip/skid indicator properly leveled on the ground first so we can be sure the ball being centered represents no slip/skid in the air. For all we know he may have moved the wing a bit too far if the ball is off. He told me how to unlock/rotate/lock the instrument. But we didn't have much time to chat about getting the plane level to set this up. Its a new Turn Coordinator and the avionics shop that installed it (last winter) probably didn't level it properly as just looking in or sitting in the plane it doesn't look quite centered.

He asked me to get the slip/skid indicator properly leveled on the ground first so we can be sure the ball being centered represents no slip/skid in the air. For all we know he may have moved the wing a bit too far if the ball is off. He told me how to unlock/rotate/lock the instrument. But we didn't have much time to chat about getting the plane level to set this up. Its a new Turn Coordinator and the avionics shop that installed it (last winter) probably didn't level it properly as just looking in or sitting in the plane it doesn't look quite centered.

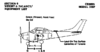

So does anyone have any advice on how/where to determine the plane is leveled first before adjusting this instrument? On the high wing Cessna's can a level be used on the underside of the wing, right above the cabin, etc.? Maybe I just measure each wingtip to ground? The slab in our hangar seems level so I think I can start there or I can move and do this outside if needed.

Also, once in cruise and all trimmed out. Can airspeed (or ground speed) be used to determine if the ball is truly centered and there is no slip or skid occurring. I didn't get much time yesterday to experiment but it seemed if I used pretty excessive ruder trim and got into a slip/skid the airspeed would drop. Maybe I was just seeing what I expected.

How you do check level on a high wing Cessna? Where to place the level?

Our last annual was pretty interesting. Did a few simple updates instead of just fixing squawks. One fix was that the plane was rolling left in cruise making it hard to fly hands free. He (A&P)termed it flying "pilot side heavy" or "pilot wing heavy"...never heard that before. I was like "Do you just adjust a aileron cable or something?". He smiles "I will tilt the wing a bit more

So this is for a Cessna 182P, probably applies to many other planes as well.

So for the pilot wing heavy he took a guess and angled it slightly more. Now, once I reach cruise I rudder trim until the slip/skid ball is dead center. I re-trim the elevator, etc. It is still just slightly pilot wing heavy. If I use a bit more rudder trim than needed (ball is now slightly left of center) it seems even better (very, very slow roll rate). But am I now uncoordinated slightly in a way that stops the left roll rate with hands off?

So my (A&P) gave me some homework LOL! Partly because he's busy and partly because he's letting me learn something I think

So does anyone have any advice on how/where to determine the plane is leveled first before adjusting this instrument? On the high wing Cessna's can a level be used on the underside of the wing, right above the cabin, etc.? Maybe I just measure each wingtip to ground? The slab in our hangar seems level so I think I can start there or I can move and do this outside if needed.

Also, once in cruise and all trimmed out. Can airspeed (or ground speed) be used to determine if the ball is truly centered and there is no slip or skid occurring. I didn't get much time yesterday to experiment but it seemed if I used pretty excessive ruder trim and got into a slip/skid the airspeed would drop. Maybe I was just seeing what I expected.