I hope you didn't make the newbie mistake of discarding that crankshaft, Dan.

I found a guy who can fix them up for us:

That crank is from an auto engine. In the world of aircraft, that sort of thing is so risky it's not funny. An auto crank delivers only torque, and a failure means coasting to the side of the road. The aircraft crank takes terrific thrust and gyroscopic precession loads as well as the torque, and often has fewer but much bigger cylinders that really make torque spikes.

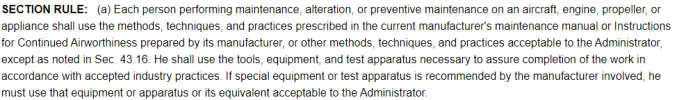

Lycoming says this in their Direct-Drive engine overhaul manual:

And this:

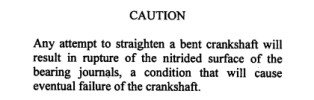

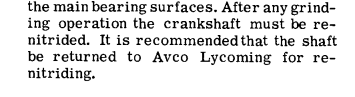

About bent cranks, Lycoming says this in their manual:

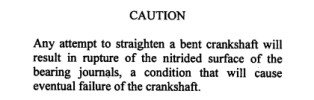

FAR 43.13 says this:

So the work must be done in accordance with the manufacturer's current manuals. Lycoming forbids the re-use of any cracked crankshaft, which would certainly cover broken crankshafts as well.

We sometimes used a nearly engine shop for cylinder work or NDT after a propstrike. The owner told me that a fellow came in one day, from the airside of the shop, and asked about the O-200 crank that was in the scrap barrel. He wanted it, and the owner would not give it to him. It was cracked between the prop flange and first main bearing surface. That crank disappeared overnight, and nothing was heard until one day the Transport guys came in and asked if they'd sold a used crank to a certain homebuilder. They had a picture of the guy, and it was the guy that wanted that cracked crank. Well, he'd swiped it, gouged out the crack, and welded it up and put it in his homebuilt. In flight, the front end of the crank broke at the weld, and the prop came off and flew up and went through the windshield, killing the guy. Crash. Legal maybe, but really stupid.

In a previous career I was the shop foreman in a machine shop where we rebuilt air brake compressors, valves, and a bunch of other stuff. Compressors are driven by the truck or earthmover's engine, and some of them had weaknesses at the drive end. Some were being driven off an engine pad and internal gearing that was designed for a hydraulic pump. But a compressor is a reciprocating load, not at all like a hydraulic pump, and it lashes the drive every time the piston goes over TDC and the residual air in the cylinder pushes the piston down, forcing the crankshaft forward, that the crank is forced back again by the next compression cycle. This beats up the drive splines.

Those cranks were expensive. Some shops were welding them up and having lots of failures. I developed a process using a MIG wire of equivalent strength to the crank's steel, and after machining all the old splines off and to a level deeper than the the weld fusion would reach, I'd weld them up carefully, two beads at a time, one on each side, and let them cool before doing any more welding. This reduced the chances of cracking in the weld interface as it cooled. Once they were all welded up, I machined them to the right diameter and cut the splines into them on the mill. They worked well unless the mechanic installed them into worn splines in the drive gear in the engine. That lash soon tore them up. That happened with brand-new cranks, too. We also did some cast iron cracks this way, but it was much more difficult due to the high carbon content of gray cast, and I had to use pure nickel wire to get adhesion. With cast, you don't want penetration or the dilution creates a hard, glass-brittle transition zone that will soon fail. The weld has to stick to the iron much like brazing would. After I left that place, they started taking shortcuts with the welding, and crank breakage happened in nearly every compressor of that drive type. I had warned them against that. Keep it cool I had said, and don't turn up the amperage. Take your time. But no, someone ignorant higher up in the company demanded speed, and got big warranty problems. Saving money no matter how much it costs, just like that homebuilder.