You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What do you think of these compressions?

- Thread starter zbrown5

- Start date

455 Bravo Uniform

Final Approach

Coming from an owner, drag car mechanic, but nonA&P, I don’t see that 65 is any real difference from 70 or 75, taking into account so many variables and differences year-over-year. Mine is maybe a bit more of a lax outlook compared to some others though. Standby for some other also valid thoughts/opinions.

timwinters

Ejection Handle Pulled

Those look good but the OH is 12 years old. My recommendation would be to make your offer assuming the engine is timed out, because it is...unless it's always been in a very dry climate.

My O-470L started making metal after 12 years and 1,500 hours and I was amazed at how much corrosion was inside when it was taken apart. AMAZED!

And I thought I was doing every right...making sure oil temps got over 180 during every flight, used camguard, dehumidified, flew it often and on long trips, etc. And it wasn't a coast plane. It was always based (and ALWAYS hangared) in various locales across the Midwest.

My O-470L started making metal after 12 years and 1,500 hours and I was amazed at how much corrosion was inside when it was taken apart. AMAZED!

And I thought I was doing every right...making sure oil temps got over 180 during every flight, used camguard, dehumidified, flew it often and on long trips, etc. And it wasn't a coast plane. It was always based (and ALWAYS hangared) in various locales across the Midwest.

Tom-D

Taxi to Parking

- Joined

- Feb 23, 2005

- Messages

- 34,740

- Display Name

Display name:

Tom-D

Understand dynamic compression, You'll understand why it doesn't matter.Coming from an owner, drag car mechanic, but nonA&P, I don’t see that 65 is any real difference from 70 or 75, taking into account so many variables and differences year-over-year. Mine is maybe a bit more of a lax outlook compared to some others though. Standby for some other also valid thoughts/opinions.

Those look good but the OH is 12 years old. My recommendation would be to make your offer assuming the engine is timed out, because it is...unless it's always been in a very dry climate.

This seems a little bit overkill to me to assume a 12 year old engine is in need of replacement. 30 years and 480 hours, maybe, but 12 years and 480 hours is on the light side of regular normal use for a private owner. I hope to put closer to 80 hours a year on the bird but still. I wouldn’t call it a “sitter”.

pigpenracing

En-Route

80/68 is damn good on a Continental....

I usually see Lycoming compression numbers a little higher than Continental.

You said you were getting a prebuy done.... The prebuy mechanic doesn't know if those numbers are good?

Why look back all those years? What matters is what the compression numbers are today.

Don't overthink things.....

I trust a old engine that runs good more than a new factory reman......

I usually see Lycoming compression numbers a little higher than Continental.

You said you were getting a prebuy done.... The prebuy mechanic doesn't know if those numbers are good?

Why look back all those years? What matters is what the compression numbers are today.

Don't overthink things.....

I trust a old engine that runs good more than a new factory reman......

80/68 is damn good on a Continental....

I usually see Lycoming compression numbers a little higher than Continental.

You said you were getting a prebuy done.... The prebuy mechanic doesn't know if those numbers are good?

Why look back all those years? What matters is what the compression numbers are today.

Don't overthink things.....

I trust a old engine that runs good more than a new factory reman......

Pre buy is next week. I’m just reviewing the owners maintenance logs. I think the internet makes it easy to over think things.

What bird is this motor hung on?

Beech Debonair.

Unit74

Final Approach

- Joined

- Mar 8, 2014

- Messages

- 6,992

- Display Name

Display name:

Unit74

Yes i am active in that forum too. I just thought since this was a general 470 engine question I’d get good response here. Why limit it to beech drivers

Unit74

Final Approach

- Joined

- Mar 8, 2014

- Messages

- 6,992

- Display Name

Display name:

Unit74

Yes i am active in that forum too. I just thought since this was a general 470 engine question I’d get good response here. Why limit it to beech drivers

Lots of very knowledgeable folks over there. ....George Braly is there... Look him up and ask him these questions.

Brad Z

Final Approach

This seems a little bit overkill to me to assume a 12 year old engine is in need of replacement. 30 years and 480 hours, maybe, but 12 years and 480 hours is on the light side of regular normal use for a private owner. I hope to put closer to 80 hours a year on the bird but still. I wouldn’t call it a “sitter”.

A professional appraiser may have a better calculation, but I make an assumption that a plane should run about 100 hours a year in order to make TBO, so an overhaul should last 20 years. I compare the hours SMOH to what it should be based on a 20 year life span. So in this case, I'd figure that it should have 1,200 hours, and calculate my offer based on that. Now if it exceeded 100/year and had more than 1,200 hours at this point, I'd use that number instead.

Kenny Phillips

Final Approach

- Joined

- Jul 29, 2018

- Messages

- 5,634

- Display Name

Display name:

Kenny Phillips

Why does everyone call leak-down test results "compressions"? They aren't: they are differential leakage numbers—leakage over time, if you will. You can also run a compression test, and the two sets of results together give you a better picture.

Unit74

Final Approach

- Joined

- Mar 8, 2014

- Messages

- 6,992

- Display Name

Display name:

Unit74

Why does everyone call leak-down test results "compressions"? They aren't: they are differential leakage numbers—leakage over time, if you will. You can also run a compression test, and the two sets of results together give you a better picture.

Because in order to do my BFR, the plane has to be good to go.....

Checkout_my_Six

Touchdown! Greaser!

so with all those compressions....what's next, dialysis?

Clip4

Touchdown! Greaser!

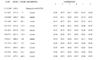

When the last 3 compression values are isolated, there is no compression issues with this engine.

The alarming number I see in your data is the plane did not fly in 2017 and only flew 41 hours over 5 years. I would be most concerned with cam corrision between the #5 and 6 cylinders. The pattern begins with minor pitting of the cam and follower that wears through the hardened surface until the soft layer beneath the hardening is breached and spalling occurs.

Have you looked at the oil change intervals over the last 5 years?

The alarming number I see in your data is the plane did not fly in 2017 and only flew 41 hours over 5 years. I would be most concerned with cam corrision between the #5 and 6 cylinders. The pattern begins with minor pitting of the cam and follower that wears through the hardened surface until the soft layer beneath the hardening is breached and spalling occurs.

Have you looked at the oil change intervals over the last 5 years?

Last edited:

flyingbrit

Pre-takeoff checklist

- Joined

- Apr 21, 2014

- Messages

- 430

- Display Name

Display name:

flyingbrit

Why does everyone call leak-down test results "compressions"? They aren't: they are differential leakage numbers—leakage over time, if you will. You can also run a compression test, and the two sets of results together give you a better picture.

For one thing, AC 43-13.1b calls it "compression" as does every A&P I've encountered.

Similarly, in my field (EE), the term "watts rms" is frequently used for audio power. This is total BS; rms properly applies only to current and voltage, not power. What is actually measured or calculated is average power, not rms. But the incorrect phraseology is so pervasive it is impossible to corrrect. The FTC even codified it into law some time ago.

thomasdr72

Pre-takeoff checklist

The great thing about Continentals, is that the bottom end tends to be moderately better in tolerating low use. The cam is near the bottom of the engine, and oil drips onto it on the way down to the oil sump. With that said, the top end (valve train) tends to be the weaker item. But hey, it's a lot easier to change a cylinder than a cam & lifters (and it gives you a great time to check the cam and lifters as well!).

V/r,

V/r,

JOhnH

Touchdown! Greaser!

Because they are smarter!Yes i am active in that forum too. I just thought since this was a general 470 engine question I’d get good response here. Why limit it to beech drivers

And because the thread over there won't devolve into cole-slaw over time.

JOhnH

Touchdown! Greaser!

Since I am not a qualified mechanic, that is one of the things I specifically look for. Both Tach/Hobbs hours between changes AND Calendar time between changes.When the last 3 compression values are isolated, there is no compression issues with this engine.

The alarming number I see in your data is the plane did not fly in 2017 and only flew 41 hours over 5 years. I would be most concerned with cam corrision between the #5 and 6 cylinders. The pattern begins with minor pitting of the cam and follower then wear through the hardened surface and wears until the soft layer beneath the hardening is breached and spalling occurs.

Have you looked at the oil change intervals over the last 5 years?

timwinters

Ejection Handle Pulled

Except an 0-470 only has a 1500 or 1600 hour TBO...I believe this is true for all of them, factory ones anyway.A professional appraiser may have a better calculation, but I make an assumption that a plane should run about 100 hours a year in order to make TBO, so an overhaul should last 20 years. I compare the hours SMOH to what it should be based on a 20 year life span. So in this case, I'd figure that it should have 1,200 hours, and calculate my offer based on that. Now if it exceeded 100/year and had more than 1,200 hours at this point, I'd use that number instead.

This seems a little bit overkill to me to assume a 12 year old engine is in need of replacement. 30 years and 480 hours, maybe, but 12 years and 480 hours is on the light side of regular normal use for a private owner. I hope to put closer to 80 hours a year on the bird but still. I wouldn’t call it a “sitter”.

I believe both Conti and Lyco also have a 12 year TBO to go along with whatever hour limit it has. Yes, it's all optional for part 91 but those numbers are good averages to base a purchase offer on. But, hey, you wanna make an offer banking on another 1200 to 1400 hours being left in the engine, well, it's your money.

Last edited:

Katamarino

Pattern Altitude

Look like perfectly good numbers for an O-470 to me!

Silvaire

En-Route

- Joined

- Oct 10, 2012

- Messages

- 4,679

- Display Name

Display name:

Silvaire

Compression tests are a diagnostic tool for the mechanic to assess the health of the engine. There’s really no purpose in keeping a record of those numbers, they’re meaningless. If you want to be picky every single one of them indicates leakage. Where? Rings? Valves? Cracked head or cylinder barrel? Busted piston? If it’s anything but rings the mechanic is going to investigate further and note any anomalies in the logbook. For a PPI you want to do a compression test now, you don’t care what someone recorded 12 years ago.

3393RP

En-Route

- Joined

- Oct 8, 2012

- Messages

- 4,219

- Display Name

Display name:

3393RP

It appears to me the 12 year old records of previous tests might show some of the larger consecutive variations are due to the mechanic's procedures and possibly the phases of the moon.

Is it acceptable to consider a range of error in the testing, say 3-5%? How much consideration should be given to repeatability deviation?

I see an 80/60 followed by an 80/70 and an 80/62 followed by an 80/71 after a period of 30 hours.

Is it acceptable to consider a range of error in the testing, say 3-5%? How much consideration should be given to repeatability deviation?

I see an 80/60 followed by an 80/70 and an 80/62 followed by an 80/71 after a period of 30 hours.

Last edited:

arnoha

Cleared for Takeoff

Continental themselves basically say not to even look into issues until it hits 80/40.

Checkout_my_Six

Touchdown! Greaser!

would you expect brand new TCMs to be 80/80?....

Tom-D

Taxi to Parking

- Joined

- Feb 23, 2005

- Messages

- 34,740

- Display Name

Display name:

Tom-D

Nearly..would you expect brand new TCMs to be 80/80?....

Landing Fees

Pre-takeoff checklist

- Joined

- Feb 9, 2018

- Messages

- 387

- Display Name

Display name:

Landing Fees

Mine is at 22 years since installed, 2275 TSMOH, purrs like an O-540

9/24/2018 2458.7 76 76 78 76 78 78

10/25/1995 75 78 79 79 79 78 Installed

9/24/2018 2458.7 76 76 78 76 78 78

10/25/1995 75 78 79 79 79 78 Installed

Chip Sylverne

Final Approach

- Joined

- Jun 17, 2006

- Messages

- 6,008

- Display Name

Display name:

Quit with the negative waves, man.

so with all those compressions....what's next, dialysis?

Defibrillator....