Yep, I checked the tooth count carefully before ordering. It’s the standard 149.

I don’t care for the lack of information or customer assistance at skytec. I called tech support. No answer. Left a message. They never returned my call. All paperwork is online. Very basic.

Received the new starter. It looks nice! Quite a difference in size an weight. I have noticed a few interesting things right off the bat with this starter. First of all, it uses metric hardware at the terminals. Seems really odd that they would do that in aviation, but whatever.

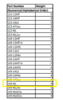

Also noticed they do not use flat washers under the star washers. The internal tooth locking washers are to be installed under the nuts/bolt and grips right into the mounting flange of the starter, rather than a typical flat washer. Not a problem, just interesting that they differ so from common installation. Out of curiosity I checked the lycoming parts manual and sure enough it shows zero flat washers for mounting. The parts manual also calls for a different length (shorter) 1 bolt for mounting the sky tec vs original.

Lastly, I noticed the installation instructions says it’s ok to cut off the unnecessary mounting. bosses.

(BOSSES 'B', 'C', & 'D' MAY BE TRIMMED TO WITHIN 1/8" OF THE STARTER CASE AND DISCARDED WHERE REQUIRED TO CLEAR OTHER DEVICES NEAR THE STARTER.)

I suppose that’s another ounce or two if I want to chop off the unused bosses that hang out in the wind for no reason on this engine