Clip4

Touchdown! Greaser!

I suppose all this is your point of view and may be true, but last time I checked the people who operate the business determine the risk/reward not the customer.Ah. Such a reliable source.

Their "view." That comes from a lack of experience and knowledge, not from any factual risks. Those same mechanics will blithely replace an engine, reconnect all the controls, fuel and oil lines, a far more complex job than opening a mag for inspection.

Slicks are easier to work on than Bendixes.

Here is what an updated 2019 article in Aviation Consumer says.

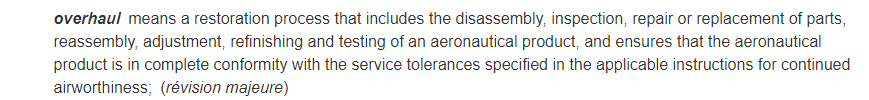

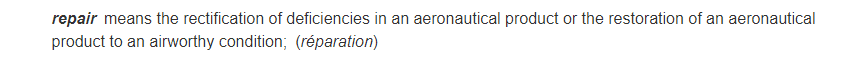

IRAN v. Overhaul

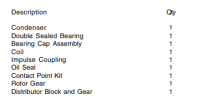

When your Bendix mags hit 500 hours in service, we recommend yanking them and sending them out to a specialized magneto shop for IRAN. For Slicks, we suggest getting an estimate for IRAN versus checking prices for rebuilt units—as they may be comparable and it can be faster to simply get rebuilt mags.We do not recommend overhauling a magneto. To tag a magneto as overhauled, a shop must replace all of a specific list of parts, even if they are perfectly serviceable. Our research into prices showed it was generally twice as expensive to overhaul a mag as to inspect and repair and replace parts as needed. Depending on the parts that have to be replaced, we figure on $500-$700 for IRAN of a big Bendix mag—the smaller mags are less expensive. Bendix mags can be IRANed indefinitely. They do not need to be overhauled.

Last edited: