azure

Final Approach

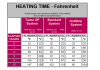

So it is cold here in Vermont, about 19F today with a stiff steady wind out of the north. I asked the FBO owner to plug in my Reiff heater last night in preparation for a flight this morning. It was plugged in all night but was out on the ramp by 0730 this morning, and I ended up not getting to the plane until about 1300. I found it still plugged in on the ramp, but with the front of the plane facing into the wind, with a wool sleeping bag draped loosely over the cowl and flapping around like crazy in the wind. I felt the cowl right under the sleeping bag and it was cool, though not cold, to the touch and putting my hand inside the oil door found that it was warmish, but not really warm. Turned on the master to read the JPI, and it said the oil temp was 54F. CHTs were in the 30s. As a result, I stayed on the ground; that's a little too cool for engine start in my book.

So my question is, does it make sense that that cool temperature was from being out in the cold wind for 6 hours after a night of good pre-heating? Or should I be looking at diagnosing and replacing a bad heater element?

So my question is, does it make sense that that cool temperature was from being out in the cold wind for 6 hours after a night of good pre-heating? Or should I be looking at diagnosing and replacing a bad heater element?