You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tire balance and runout tolerances

- Thread starter manac

- Start date

Are you talking about the mains or a nose wheel?Can’t find any spec for runout.

What's the reason to check?

I don't believe there are any specific OEM tolerances.

manac

Pre-takeoff checklist

- Joined

- Oct 16, 2007

- Messages

- 262

- Display Name

Display name:

Manac

BothAre you talking about the mains or a nose wheel?

What's the reason to check?

What’s to say something is good or bad without some sort of limit?

Cessna service manual says to “static balance the tire wheel assembly”.

Without some sort of specification what’s to prevent me from putting the assembly on the machine and taking it off and calling it balanced?

Yes I realize static balancing is done to best effort, whatever that is.

Not everything needs a limit. For the mains, the wheels and tires are made to a standard specification and provided you orientate the tire to the wheel assy correctly, you should have no or limited balance issues. Mains rarely get dynamically balanced unless there is an issue at landing or take-off speeds which usually is tire issue and not a balance issue.What’s to say something is good or bad without some sort of limit?

The nose wheel is different due to shimmy issues. There are times when a dynamic balance is needed. However, outside of the old Cessna Service Center network there was no process published so you basically had to apply other existing processes to balance the wheel. Cessna had a few bulletins out on this topic but I don't recall they offered much on the process except only to balance the wheels. I think there are several threads on PoA that give some good examples of what can be used to balance wheels.

Last edited:

Clip4

Touchdown! Greaser!

With 15-600-6 mains and some static balance is a good thing.Not everything needs a limit. For the mains, the wheels and tires are made to a standard specification and provided you orientate the tire to the wheel assy correctly, you should have no or limited balance issues. Mains rarely get balanced unless there is an issue at landing or take-off speeds which usually is a tire issue and not a balance issue.

The nose wheel is different due to shimmy issues. There are times when a dynamic balance is needed. However, outside of the old Cessna Service Center network there was no process published so you basically had to apply other existing processes to balance the wheel. Cessna had a few bulletins out on this topic but I don't recall they offered much on the process except only to balance the wheels. I think there are several threads on PoA that give some good examples of what can be used to balance wheels.

Gary Ward

En-Route

I have been wrestling with balancing tires for close to 40 years on my fleet of work trucks and race cars. And the last 6 years aircraft tires.Anyone have a source for tolerances?

Used ISO 1940 G40 for balancing.

It comes out to a little less than an oz in for an 11lb tire wheel assembly @ 120 MPH.

Can’t find any spec for runout.

What I have found is not so much runout, but out of round. Many tires are out of round and you can balance them until you are blue in the face and a good balance job does not fix out of round.

To me the tolerance is whether they run smooth or not.

I have several wheel balance rs, static, spin dynamic , strobe and the most effective is a tire lathe.

The lathe makes the tire round and then it runs very smooth. Then normally a balance is not required. But the lathe only works on larger tires from light trucks on up. So it is too big for most GA aircraft tires.

I also have a mcfarlane static balance for both wheels and propellers. It works but does not fix out of round. I am betting many aircraft tires are. Mcfarlane recomends a belt sander to true aircraft tires which I have done with reasonable success to make them round.

I did have a main on my 172 that had too much runout. I noticed it mostly because my brake rotor was rubbing when I taxi and when I push the plane back into the hangar. I found the outer bearing race spinning in the wheel causing the runout. A replacement wheel was the fix for that.

Gary Ward

En-Route

This is a tire lathe, it is very effective to make truck tires run smooth by truing them.

I mount new tires and run them for approx 200 miles and then true them warm right off the road.

The little bit of tread that you cut off makes them round and extends the life of them and everything else on the truck including the driver.

I mount new tires and run them for approx 200 miles and then true them warm right off the road.

The little bit of tread that you cut off makes them round and extends the life of them and everything else on the truck including the driver.

Last edited:

MajorTurbulence

Line Up and Wait

- Joined

- Jan 9, 2013

- Messages

- 715

- Display Name

Display name:

MajorTurbulence

How do you know if it is the rim out of round and not the tire? I guess it would not matter much since your tire lathe takes care of the roundness of the combination.I have been wrestling with balancing tires for close to 40 years on my fleet of work trucks and race cars. And the last 6 years aircraft tires.

What I have found is not so much runout, but out of round. Many tires are out of round and you can balance them until you are blue in the face and a good balance job does not fix out of round.

To me the tolerance is whether they run smooth or not.

I have several wheel balance rs, static, spin dynamic , strobe and the most effective is a tire lathe.

The lathe makes the tire round and then it runs very smooth. Then normally a balance is not required. But the lathe only works on larger tires from light trucks on up. So it is too big for most GA aircraft tires.

I also have a mcfarlane static balance for both wheels and propellers. It works but does not fix out of round. I am betting many aircraft tires are. Mcfarlane recomends a belt sander to true aircraft tires which I have done with reasonable success to make them round.

I did have a main on my 172 that had too much runout. I noticed it mostly because my brake rotor was rubbing when I taxi and when I push the plane back into the hangar. I found the outer bearing race spinning in the wheel causing the runout. A replacement wheel was the fix for that.

Last edited:

Checkout_my_Six

Touchdown! Greaser!

This....I've also seen where the rim begins to split or widen. That changes things too.How do you

How do you know of it is the rim out of round and not the tire? I guess it would not matter much since your tire lathe takes care of the roundness of the combination.

Gary Ward

En-Route

Yup that is the beauty of the lathe, it does not matter. Todays wheels it's pretty hard to put them on wrong. They are within a few thou and tires can be + or _ .250"How do you know if it is the rim out of round and not the tire? I guess it would not matter much since your tire lathe takes care of the roundness of the combination.

Long time ago I serviced split rim and bud wheels. Those were hard to get mounted true on the hubs. Don't have that challenge today.

Last edited:

MajorTurbulence

Line Up and Wait

- Joined

- Jan 9, 2013

- Messages

- 715

- Display Name

Display name:

MajorTurbulence

If a lathe cannot to be used for the small aviation tires, then what can you you do to ameliorate an out of round tire/rim combination? Can you ask the dealer to true out the tires before delivery?But the lathe only works on larger tires from light trucks on up. So it is too big for most GA aircraft tires.

Truing up a rim, if out of round would seem to require purchasing a new true rim. But is there a way to true out a split rim wheel already in use that is found to be out of round without a new rim purchase?

On the aviation side, the wheel OEM will have guidance on what is possible but in my experience I haven't run across any approved repairs for a bent or distorted wheel.But is there a way to true out a split rim wheel already in use that is found to be out of round without a new rim purchase?

Dan Thomas

Touchdown! Greaser!

- Joined

- Jun 16, 2008

- Messages

- 11,430

- Display Name

Display name:

Dan Thomas

Bent or cracked or distorted wheels must be replaced. They are cast aluminum, then the inside of the flange and bead seat and the radius between them is roller-hardened to discourage cracking. And welding or straightening is going to just make things worse.On the aviation side, the wheel OEM will have guidance on what is possible but in my experience I haven't run across any approved repairs for a bent or distorted wheel.

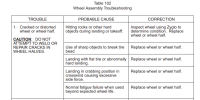

From the Cleveland manual:

No permissible damage repairs mentioned anywhere.

The cast wheels are machined in a lathe, and the bearing bores and bead seats and flanges are all concentric. No runout to speak of. It's the tires that are the problem. Even a cheap car tire is often more concentric than a $200 aircraft tire.

Using a lathe or McFarlane's belt-sander idea will get the tire round, but that does not mean balanced. The inside of the tire could be eccentric, too. Mains can get statically balanced to stop the shake, but statically-balancing a nosewheel might stop the vertical shake and make the wobble (shimmy) much worse, depending on where the balance weights are placed. A static balancer cannot tell you what side to put those weights on, or how to split them up between one side and the other. A dynamic balance is necessary for that, and aircraft shops almost never have such equipment. A bigger motorcycle shop can sometimes do it. I modified an old automotive dynamic balancer to do it, and later built my own in another shop. Stops nosewheel shimmy dead.

Danny Camp

Filing Flight Plan

- Joined

- Jan 14, 2022

- Messages

- 16

- Display Name

Display name:

piloteer01

Bent or cracked or distorted wheels must be replaced. They are cast aluminum, then the inside of the flange and bead seat and the radius between them is roller-hardened to discourage cracking. And welding or straightening is going to just make things worse.

From the Cleveland manual:

View attachment 125772

No permissible damage repairs mentioned anywhere.

The cast wheels are machined in a lathe, and the bearing bores and bead seats and flanges are all concentric. No runout to speak of. It's the tires that are the problem. Even a cheap car tire is often more concentric than a $200 aircraft tire.

Using a lathe or McFarlane's belt-sander idea will get the tire round, but that does not mean balanced. The inside of the tire could be eccentric, too. Mains can get statically balanced to stop the shake, but statically-balancing a nosewheel might stop the vertical shake and make the wobble (shimmy) much worse, depending on where the balance weights are placed. A static balancer cannot tell you what side to put those weights on, or how to split them up between one side and the other. A dynamic balance is necessary for that, and aircraft shops almost never have such equipment. A bigger motorcycle shop can sometimes do it. I modified an old automotive dynamic balancer to do it, and later built my own in another shop. Stops nosewheel shimmy dead.

Danny Camp

Filing Flight Plan

- Joined

- Jan 14, 2022

- Messages

- 16

- Display Name

Display name:

piloteer01

Thank you for this. Just wish every shop had one. Seems like it would be necessary equipment.

SoCal 182 Driver

Cleared for Takeoff

- Joined

- Sep 11, 2019

- Messages

- 1,072

- Display Name

Display name:

SoCal 182 Driver

A bit of thread drift...

Can anyone recommend a decent (and reasonably priced) static balancer for my C182 tires?

Thanks!

Can anyone recommend a decent (and reasonably priced) static balancer for my C182 tires?

Thanks!