If one were to cut some lumber into chocks, how would you do it?

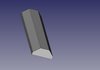

1. Rip cut a 4x4 into symmetrical pentahedrons on the table saw.

2. Rip cut a 2x4 into symmetrical trapezoid-based tetragonal prisms.

3. Grab some 2x2 from the cull lumber pile and call it a day.

Ignoring the 1/8" kerf, here's pics of the first 2 options. The third should be self-explanatory.

1. Rip cut a 4x4 into symmetrical pentahedrons on the table saw.

2. Rip cut a 2x4 into symmetrical trapezoid-based tetragonal prisms.

3. Grab some 2x2 from the cull lumber pile and call it a day.

Ignoring the 1/8" kerf, here's pics of the first 2 options. The third should be self-explanatory.