I dunno. From 200 to 400 hours the increase was nearly 20%. And the sheer fact that half of engines crash before they make it to 400 hours whether mechanical failure or not is insane to me.

Again, that's half of the airplanes *that crashed*. Not half of all homebuilts with that engine.

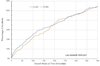

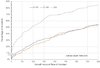

Here's a plot I recently posted to another forum. It shows the number of Lycoming engines installed in the homebuilt fleet as of January 2023, both from active registrations and from de-registered airplanes:

Almost 6,000 homebuilts have had one of the O-360 series installed in them. This does not include the ~3,300 homebuilts that don't list a specific engine type ("AMA/EXPR"). About a quarter of those are production-type engines. I think we can safely round it up to 6,000 airplanes.

Out of those 6,000 homebuilts, there have been 38 cases of accidents caused by an O-360-series engine mechanical failure...

over a 22-year period. Less than two per year.

As far as "crashing before 400 hours," remember, that MOST homebuilts don't fly as much as production airplanes. The FAA General Aviation Survey estimates homebuilts fly about 47 hours a year. My own estimate based on accident report data is about 50 hours per year. Using the same process on my ~3300 Cessna 172 and 210 accidents, I get 250 hours a year. The AVERAGE Cessna 172/210 in that database has 5,200 hours, compared to 355 hours for the homebuilts.

A typical GA airplane with a thousand hours is considered almost new. A homebuilt with a thousand hours on it is admitted to a special parking area at Oshkosh, and no doubt has the aircraft equivalent of walkers available. Shoot, my Fly Baby was completed in 1980, and, other than a few repair periods, has been in continuous use since. It's got ~800 hours, of which ~700 were flown by me.

So *most* of the homebuilt accidents you see are going to be low-time aircraft, at least by the standards of production-type GA aircraft.

Ron Wanttaja