Auto engine conversions have proven unreliable in aircraft applications. Frankly, I wouldn’t want to fly behind any of them.

Always hard to establish the safety record of auto-engine conversions, because FAA records don't reliably establish the number of specific engines in the fleet. About 15% of Experimental Amateur-Built aircraft are merely listed as having "AMAT/EXP" engines. There's nothing to prevent a company selling conversions as claiming the majority of those are theirs. It should be noted that one company, at least, claims an installed base that is ten times higher than the US records reflect (although non-US engines can mess up such comparisons).

In addition, there is no standardization for identifying the auto engine types. An FAA (or NTSB...) record saying the aircraft has a Great Plains conversion is pretty definite, but if the record says Volkswagen that DOESN'T mean it's NOT a Great Plains conversion.

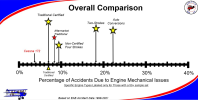

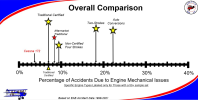

I use two methods to examine engine safety statistics. The first completely ignores the installed base, and uses exclusively NTSB accident reports. This method computes the percentage of accidents that were caused by engine mechanical failures:

Note, again, the percentages is the percentage of ACCIDENTS, not the percentage of the entire installed fleet. This plot DOES NOT MEAN that 22% of auto engines suffer a mechanical issue, just that 22% of the known accidents were due to engine issue.

And for homebuilts, the "known accidents" issue can be important, because homebuilts are much more suited to disassembly and removal from the crash site before the local gendarmerie arrives....

Anyway, as the above shows, when accidents happen, it's about three times the likelihood that an auto-engine had an issue than a conventional engine.

However, this sort of statistic messes people up a bit. They expect to see an accident rate for the entire fleet...hence my capitalized reminders above.

I have made a stab at estimating the number of installed engines. As I mentioned, about 15% of the homebuilts don't list a specific engine. However, NTSB reports are a bit better. I cross-referenced the list of AMAT/EXP engines in the FAA registry with the NTSB reports, and got the engine types for about 150 AMAT/EXP engines. I use that data compute the estimated percentage of the AMAT/EXP fleet that are particular engine types. It's done for both the active aircraft as well as the de-registered ones.

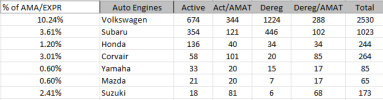

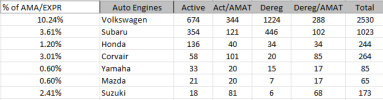

Here's what the auto-engine conversion numbers look like:

About 10.24% of the AMAT/EXP engines in the crosslisted NTSB list were VWs, so I applied that percentage to the number of AMAT/EXP engines in both the active and deregistered aircraft list to compute the estimated total number of installed engines. Note that there have been about four times the number of homebuilts with VW engines than the current registry reflects. Other types do not see as much of an increase.

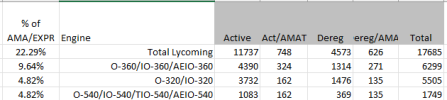

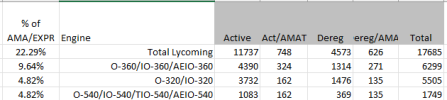

For comparison, here's the same data for Lycoming:

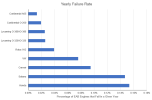

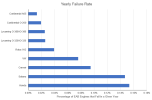

With that, I can estimate how often a given type of engine fails in a given year (for homebuilts):

It's not on the graphic, but the worst-case I saw was a common two-stroke engine, with an installed base of ~780 engines and a 0.245% annual failure rate.

Now, consider how "serious" the failure rates are. The Honda, for instance, has a ~0.15% annual failure rate...ZERO point 15 PERCENT. That's one accident each year for ~600 aircraft. My 22-year accident database shows only 9 accidents where the Honda engine was a causal factor. That's really not that bad.

Of course, my processes have their issues. I examine homebuilt accidents from 1998-2021, for example, and the aircraft in the deregistered list may come from far before that time period...makes the results a bit better.

Also, based on the percentage of the number of accidents (the first graphic), the Rotax 912 and the Continental O-200 come out about the same. But as you can see in the last graph, the 912 is higher than the O-200. The Rotax fleet size is difficult to determine, since not only are there engines listed as AMAT/EXP, there are listings showing generic "Bombardier" or "Rotax" engine types without a specific model. These could be 912s, and equally could be two-stroke 582s. I have run a similar process to try to identify the Bombardier or Rotax engine types.

Ron Wanttaja