Sjensen

Filing Flight Plan

During my plane's recent annual inspection, I had to replace the #4 cylinder and rebuild the carburetor. This was my first time dealing with both of these issues, so I wasn't sure what to expect. However, I've noticed a significant loss of power, especially during climb-out, and a decrease in RPM performance. Previously, I could achieve around 2700 RPM at full throttle in the air. Now, it struggles to reach even 2500 RPM and typically hovers around 2300 RPM at full throttle.

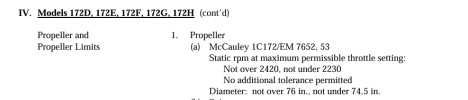

My question is simple: Is this normal when breaking in a new cylinder? Is it typical to experience a 400 RPM loss during this break-in period, and will the power return once the cylinder is fully broken in? Or could there be an issue with how the carburetor was re-installed? For reference, my plane is a 1966 Cessna 172G with an O-300 engine, and the #4 cylinder was replaced with a Superior Millennium cylinder (SA10200-A20P).

Any help or advice would be greatly appreciated!

Thanks,

Spencer

My question is simple: Is this normal when breaking in a new cylinder? Is it typical to experience a 400 RPM loss during this break-in period, and will the power return once the cylinder is fully broken in? Or could there be an issue with how the carburetor was re-installed? For reference, my plane is a 1966 Cessna 172G with an O-300 engine, and the #4 cylinder was replaced with a Superior Millennium cylinder (SA10200-A20P).

Any help or advice would be greatly appreciated!

Thanks,

Spencer