alaskan9974

Pre-takeoff checklist

Oil temp is running low in cruise in winter, taped cooler on my bonanza and 182 to get them into the green in cruise but the pa-32 is cowled a little better, what oil temp should I try for, 140-180?

I use aluminum foil tape it doesn’t seem to break, my oil temps are just above green in cruise, 90-100Be careful using tape. Air pressure against the oil cooler can push the tape into the fine holes in the radiator style cooler and block airflow in the summer when you really need the cooling. It's a b**ch to clean. Most manufactures have a metal plate for a "winterization kit".

Normally temperatures need to be above 180F for 30min to boil the moisture contaminants out of the oil. It's hard to get that high a temp in winter. I saw 160F two weeks ago on the Pawnee O-540 on a warm early winter day, about 40F OAT.

someone in the club put the foil "furnace tape" on an oil cooler once.. we made him spend the next 3 hours clearing it out of the holes after his 6hr cross country.I use aluminum foil tape it doesn’t seem to break, my oil temps are just above green in cruise, 90-100

The TCDS for just about any engine or airplane list the redline oil inlet temperature. Pretty hard to do that if the probe is just any old place. It's usually somewhere just downstream of the oil cooler return line.It’s going to depend on where your temperature probe is located in the oil system.

I've used aluminum foil tape in the winter on my oil cooler for 20 years. Never a problem.I use aluminum foil tape it doesn’t seem to break, my oil temps are just above green in cruise, 90-100

I think there is some law about that. Can't remember where. Some one here in Canada got into some difficulty with the feds. They saw it as an unapproved modification or something. A taped-off vent can present serious difficulty if your carbon monoxide detector tells you that you're about to die if you don't get some fresh air into the cabin. Or if you get a fire of any sort that requires discharging the extinguisher in the cabin. That fills the air with obscuring dust. Smoke from the fire also blinds the pilot. Electrical fires in small airplanes are not rare. Check the landing/taxi light switches in your 172; they are famous for melting down and burning up under the higher current loads. Your LED lights go a long way toward avoiding that. An incipient problem can be spotted by noting discolored insulation on the wire crimp terminals on the switch. It starts to get dark.I also tape off the fresh air intake openings in the wing to help keep the cold air out of the cabin.

I think there is some law about that. Can't remember where. Some one here in Canada got into some difficulty with the feds. They saw it as an unapproved modification or something. A taped-off vent can present serious difficulty if your carbon monoxide detector tells you that you're about to die if you don't get some fresh air into the cabin. Or if you get a fire of any sort that requires discharging the extinguisher in the cabin. That fills the air with obscuring dust. Smoke from the fire also blinds the pilot. Electrical fires in small airplanes are not rare. Check the landing/taxi light switches in your 172; they are famous for melting down and burning up under the higher current loads. Your LED lights go a long way toward avoiding that. An incipient problem can be spotted by noting discolored insulation on the wire crimp terminals on the switch. It starts to get dark.

Those Cessna vents are indeed leaky. I installed several sets of these for customers:

https://www.aircraftspruce.com/catalog/appages/ventube.php?clickkey=3080433

Never, ever have a dry chemical fire extinguisher in an airplane. It's a sure way to be in IMC regardless of weather.Or if you get a fire of any sort that requires discharging the extinguisher in the cabin. That fills the air with obscuring dust. S

I found a set for 301 pa-32's but none around that I saw for the PA-32 cherokee I have, will just stick to tape until I find something correct for it. Should I shoot for midrange on the gauge? The oil temp struggles to stay above 120 when its warm around 0f, but is lucky to get above 100* when oat reaches -30 and colder.The TCDS for just about any engine or airplane list the redline oil inlet temperature. Pretty hard to do that if the probe is just any old place. It's usually somewhere just downstream of the oil cooler return line.

There used to be a guy who sold metal plugs to cap off those inlets. Worked pretty good from what I remember. But don't recall anymore than that.I also tape off the fresh air intake openings in the wing to help keep the cold air out of the cabin.

160F is fine, 180F is better. I wouldn’t want it any higher.

Religion is controversial, but I feel perfectly comfortable with 160F assuming it’s flown long enough. Temperature matters less than frequency and duration of operation.IMHO 160ºF is too cold. 180-220ºF is where oil should run. From Blackstone labs: "We measure the viscosity at 210°F, which is in the neighborhood of your engine oil at operating temperature at cruise." https://www.blackstone-labs.com/about-aircraft-oils-2/

Flying today in 56ºF OAT my cruise oil temp was 179ºF which, to me, is not warm enough.

To each their own ...

Edit: https://www.eaa.org/eaa/news-and-pu...-2017-control-of-your-engines-oil-temperature

Religion is controversial, but I feel perfectly comfortable with 160F assuming it’s flown long enough. Temperature matters less than frequency and duration of operation.

They were made by SAIR Corp and they are nice. He made lots of nice stuff but no longer in business.There used to be a guy who sold metal plugs to cap off those inlets. Worked pretty good from what I remember. But don't recall anymore than that.

Normally temperatures need to be above 180F for 30min to boil the moisture contaminants out of the oil.

Have heard that stated many times as an established fact. But I wonder whether there is any science or test data to support it, or if it is just a useful rule of thumb that has been repeated so often it has become truthy.

We were fortunate to talk with Paul Royko, AeroShell’s Technical Manager of piston-engine oil, who speaks frequently at aviation events and conferences. Though he won’t admit to it, Royko is something of an aviation-oil guru, and his advice is something all pilots can benefit from.

Royko advises flying as often as possible. In today’s economic doldrums, flying often may not be feasible, so he offers this advice: “The key to reducing corrosion is flying long enough at the proper oil temperature.” Royko explains that pilots need to fly at an oil temperature of 180 to 190 degrees F for at least an hour so water will boil away.

“Water boils off at 212 degrees Fahrenheit, and the actual temperatures experienced by the oil inside the engine are about 50 degrees higher than at the oil-temperature gauge,” Royko says. “Flying at lower oil temperatures or for less time might actually promote more moisture, not less.”

I wonder if it would be more legal if I used FAA-PMAA approved duct tape in instead of 3M?I think there is some law about that. Can't remember where. Some one here in Canada got into some difficulty with the feds. They saw it as an unapproved modification or something. A taped-off vent can present serious difficulty if your carbon monoxide detector tells you that you're about to die if you don't get some fresh air into the cabin. Or if you get a fire of any sort that requires discharging the extinguisher in the cabin. That fills the air with obscuring dust. Smoke from the fire also blinds the pilot. Electrical fires in small airplanes are not rare. Check the landing/taxi light switches in your 172; they are famous for melting down and burning up under the higher current loads. Your LED lights go a long way toward avoiding that. An incipient problem can be spotted by noting discolored insulation on the wire crimp terminals on the switch. It starts to get dark.

Those Cessna vents are indeed leaky. I installed several sets of these for customers:

https://www.aircraftspruce.com/catalog/appages/ventube.php?clickkey=3080433

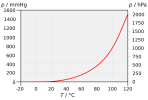

Now, I am no physicist, but water doesn't need to get to boiling to evaporate. Its vapor pressure rises dramatically with temperature, like so:Have heard that stated many times as an established fact. But I wonder whether there is any science or test data to support it, or if it is just a useful rule of thumb that has been repeated so often it has become truthy.

That there, but really low oil temps aren't helping.Somewhere in the engine crankcase, the temperature is way way high enough to boil water.

Not really. The data for Aeroshell 15W50, for example, shows a flashpoint (gives off flammable vapors) of 238°C (460°F). The oil is starting to coke then, forming carbon deposits everywhere. Its viscosity also gets too low at elevated temperatures and it doesn't lubricate well when it's so thin, and can't cool well. It's all why we have oil coolers.Dan Thomas listed some Lycoming data earlier showing the desired temp to be mostly 180-245ºF (although I think 245 is too hot).

It happens. I have had old switches melting. The switch contacts oxidize, introducing resistance and therefore heat is generated. The crimp terminals and the wire inside them oxidize, too, and they can get hot and that heat travels through the switch terminals into the switch. It's one reason why Cessna now wants the landing, taxi and master switches replaced every four years or so.Wiring melting down? your freaking me out.

Oh man, stop it with the replacement ideas!!It happens. I have had old switches melting. The switch contacts oxidize, introducing resistance and therefore heat is generated. The crimp terminals and the wire inside them oxidize, too, and they can get hot and that heat travels through the switch terminals into the switch. It's one reason why Cessna now wants the landing, taxi and master switches replaced every four years or so.

View attachment 123528

https://www.tsb-bst.gc.ca/eng/rapports-reports/aviation/2007/a07o0264/a07o0264.html

It's not bad if all the sketchy stuff is fixed; keeping it up-to-date means small inspections and repairs here and there instead of that first-annual shocker that the next owner faces. Our fleet's maintenance costs were not bad at all, but when we bought another airplane we went through it and fixed everything. That meant an airplane that didn't let down the students, especially far from home. And it made life easier for me in the long run.Oh man, stop it with the replacement ideas!!

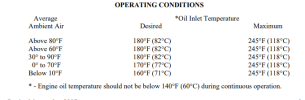

The vernatherm in my AA-5 seems to maintain these temperatures perfectly: 180F above 0C and not under 170F below 0C.Why don't we see what an engine manufacturer says about it? From Lycoming's O/IO-360 Operator's Manual:

View attachment 123504

https://www.lycoming.com/sites/default/files/attachments/O-HO-IO-HIO-AIO%20%26%20TIO-360%20Oper%20Manual%2060297-12.pdf

My personal policy prior to my recent restoration was to replace any hardware and standard parts that I touched during a maintenance process. Not that it was necessary, but I just figured why reuse 45 year old stuff if you have a new one handy. That was especially the case for switches, breakers, etc. One less thing to have an issue with.It's not bad if all the sketchy stuff is fixed; keeping it up-to-date means small inspections and repairs here and there instead of that first-annual shocker that the next owner faces. Our fleet's maintenance costs were not bad at all, but when we bought another airplane we went through it and fixed everything. That meant an airplane that didn't let down the students, especially far from home. And it made life easier for me in the long run.

I have two OT sensors. Primary on the pressure screen housing, and alternate on a port on the front of the case. The alternate consistently reads 15 degrees higher than the primary.The TCDS for just about any engine or airplane list the redline oil inlet temperature. Pretty hard to do that if the probe is just any old place. It's usually somewhere just downstream of the oil cooler return line.

Seemed to work fine in the summer, this was at -40 oat on landing.How confident are you in that guage?

If the oil is actually that cold I'd be suspicious of the vernatherm. That said, when my oil is that cold my oil pressure is up in the hundreds. Also, the oil temp will get over 100 just idling after startup, even on the coldest days.Seemed to work fine in the summer, this was at -40 oat on landing.