If the Gen is operating normal with Field grounded then it’s likely

the issue lies in the Regulator Circuit.

The Master is a dual pole single throw switch with one side

completing Ground Circuit for the Battery Contactor and the other

makes or breaks the Field Circuit.

Suggest you jump the Field side.

Rather than do it at the Switch you want to jump from the

Field terminal on Gen to the Field terminal on Regulator.

We messed with it some more tonight - no luck - see what you can make of this

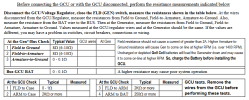

- we removed the wires from the VR - attached bat and arm together and started the engine, yes with avionics off, then touched the field wire to ground - ran engine up slowly and around 1300 the voltmeter started up and by 1700rpm was putting out about 13.3 volts - (we assume this indicates the generator is/can charging)

- Also, since we were grounding the field wire, we assume this verifies the master switch connections are good - as I read the diagram the field wire goes from VR to master then to the field terminal on gen - can you confirm or refute

- next we removed the zeftronics and installed another delco VR we had - gen would not come online - just to see if we could get it to charge we grounded the field wire on the VR, expecting it to start charging but it didnt -

- nothing I have read explains to me why grounding the field wire will result in charging if the bat and arm wires are connected but it they are installed on their respective VR terminals then directly grounding the field wire doesn't work

- in checking continuities and resistance we found no readings of extremely high resistance

- We did flash the generator following the zeftronics instructions of grounding the field wire, master on and touch together bat and arm for 3-5 seconds and repeat

- The only readings we got that is a mystery at least to us is - we measured .6 volt of residual current with master off at the arm terminal on gen - after flashing we got a reading of 1.6V and after running the engine and verifying that it was not going to start charging we shut down the engine and turned off the master and again checked the residual got a reading of 0V

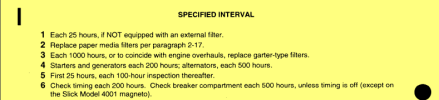

I recall reading that the zeftronics needed to see a min of 1.5V residual to activate -

Not sure if my issues are related this lack of residual V or maybe we are not checking it correctly

As far as someone asked about checking the brushed, yes the brushes and springs were inspected a few months ago during annual and reported to look serviceable

The generator has done a good job the past 5 years until this issue - if it's something simple we are missing would like to run the gen a few more years but at the moment it's starting to look like an alternator is in the near future