These air boxes are made of light steel sheet. They're actually a Continental part. They are entirely supported by the carb.

Now, think about this: Every time a cylinder fires, the mass of the propeller causes the engine to rotate a little bit in the opposite direction of prop rotation. Prop torque reaction. That carb airbox is a long way below the crankshaft centerline, so when the engine fires it gets jerked sideways a bit. That causes flexing of the box around that neck where it's spot-welded to the box itself, and when you bend metal often enough for a long time, it work-hardens and cracks. Steel is better this way than aluminum, and aluminum airboxes are frequently troublesome. We often find some horrific repairs on airboxes, and it seems that some guys don't understand that an airbox failure can mean an engine failure.

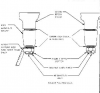

The O-200 is supposed to have four Lock-O-Seal washers on the carb spider (intake manifold) installation to the crankcase. They are washers that have a rubber O-ring molded into them. The nuts that hold it on are supposed to be finger-tight and cotter-pinned. The whole thing--spider, carb and airbox-- is supposed to be able to flex sideways a fraction of an inch. That does two things: It keeps that silly carb happy, since vibration tends to shake fuel out of the bowl vent and into the carb throat, where it causes uneven and rich mixtures and rough running, and it minimizes the shaking of that airbox. This particular airplane probably doesn't have the proper washers, or the nuts have been tightened way too much, or it spent some time in the past like that.