You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

172 seats

- Thread starter Jfarrer

- Start date

pilotshashi

Ejection Handle Pulled

ReclinerI have a 1960 Cessna 172B. My seats need an upgrade, anyone know of a way to replace them or upgrade them? I mainly want something that will recline.

Thanks!

Dan Thomas

Touchdown! Greaser!

- Joined

- Jun 16, 2008

- Messages

- 11,360

- Display Name

Display name:

Dan Thomas

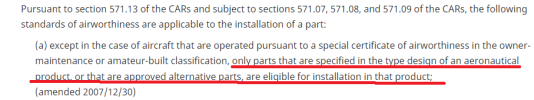

Using parts from a later model can get problematic. Somewhere in the FARs there is (or was) a requirement that only parts specified in the manufacturer's parts catalog for that serial number or airplane could be installed, or their equivalent such as a PMA'd part, or under an STC. The parts catalog will have listings of various seat part numbers that are eligible for installation on certain serial number ranges; this constitutes part of the "Type Design" that has to be maintained. Bell206 would have the reliable opinion on this. In Canada we have this rule:

Besides that, finding a serviceable used infinitely-adjustable Cessna seat will be difficult. And expensive, since everyone else wants them or wants parts off them. Parts for these seats are horrifically expensive.

These things are getting old (the 172M dates to 1974-'76 or so, 50 years ago) and they have structural weaknesses such as cracking seat bottom frame legs, wallowed-out roll pin holes, worn seat-back adjustment cams, and worn clevis pins that run on those cams I've found those pins worn more than halfway through; if one failed on takeoff, the other, now bearing the entire load, could fail and the seat back flops back. The pilot instinctively pulls himself forward using the controls, and the resulting stall and crash can be fatal. All because mechanics never looked at those little two-bit pins at annual inspection. The seat height adjustment relies on an acme-threaded rod, rotated by a crank, in a machined aluminum nut. That nut's threads wear out and tear out and the seat suddenly drops to its lowest level.

Your 172B seat likely has one locking pin, so only one seat rail has the pin holes drilled in it. 172M's have two locking pins, and both rails are drilled. Now you're looking at more mods and more 337s or whatever.

Besides that, finding a serviceable used infinitely-adjustable Cessna seat will be difficult. And expensive, since everyone else wants them or wants parts off them. Parts for these seats are horrifically expensive.

These things are getting old (the 172M dates to 1974-'76 or so, 50 years ago) and they have structural weaknesses such as cracking seat bottom frame legs, wallowed-out roll pin holes, worn seat-back adjustment cams, and worn clevis pins that run on those cams I've found those pins worn more than halfway through; if one failed on takeoff, the other, now bearing the entire load, could fail and the seat back flops back. The pilot instinctively pulls himself forward using the controls, and the resulting stall and crash can be fatal. All because mechanics never looked at those little two-bit pins at annual inspection. The seat height adjustment relies on an acme-threaded rod, rotated by a crank, in a machined aluminum nut. That nut's threads wear out and tear out and the seat suddenly drops to its lowest level.

Your 172B seat likely has one locking pin, so only one seat rail has the pin holes drilled in it. 172M's have two locking pins, and both rails are drilled. Now you're looking at more mods and more 337s or whatever.

wheaties

Pre-takeoff checklist

Having sat in the early cessna seats vs the newer adjustable, I'd take the early ones. The lack if movement is a con but they are infinitely more comfortable on a skinny butt than any other aircraft I've sat in. That's a serious pro. To me, they add the one speed mod you just can't beat; an extra hour in the air.

Deelee

Pattern Altitude

- Joined

- Feb 12, 2019

- Messages

- 1,783

- Display Name

Display name:

Deelee

In a similar situation - 1969 Arrow with non-headrest front seats.... would like to add seats with headrests as part of an interior renovation. Nope. Can't modify the existing seat frames to add headrests without FSDO getting involved since modifying seat frames is considered a major alteration. And that just sounds like a massive PITA and who knows how long it would take. Can't swap seats from a newer Arrow since the part numbers are different for the newer seats.

Meh. Guess the low-backed front seats aren't that bad, after all. Another tic in the 'let's go EAB next time' column.

Meh. Guess the low-backed front seats aren't that bad, after all. Another tic in the 'let's go EAB next time' column.

- Joined

- Dec 5, 2010

- Messages

- 5,500

- Display Name

Display name:

GeorgeC

I had to go through the FSDO when a shop (unnecessarily, IMO) decided it was a major alteration to install a bracket in my battery box to fit the Odyssey battery. It didn't take too long, at least relative to the geologic timescale I'm accustomed to with all things aviation.

might be some useful info for you here

If by upgrade you mean installing a Cessna vertical adjusting seat then you have options. However, would need an airframe S/N to determine which route.My seats need an upgrade, anyone know of a way to replace them or upgrade them?

It can be in some cases but in most there is a way to swap 100 series front seats. In a previous revision of the Cessna 100 series maintenance manual, there was a statement in Ch 3 that effectively said any adjustable seats could be installed in all 100 series models except the 150.Using parts from a later model can get problematic.

However, at some point that statement was removed in a later revision. I don’t know if it was removed when the 2-pin locking mech was released or when the restart vertical adj seat AD was issued.

Regardless, the easiest route is to find an old revision of the 100 series MM with that statement and change out the seats as a “replacement" using that reference or, use Plan B and treat it as a minor alteration and swap seats. Just be sure if you install a 2-pin seat on a 1-pin tracks you replace the floor track to accommodate the 2nd lock pin. Or change both tracks as they usually need replacing. This was one of the reasons I was always a fan of keeping and using old manuals for old aircraft.

FYI: while I never dealt with it, if the donor aircraft is a restart 172 or 182 then you must ensure you track the seat AD has it was applicable by aircraft model and not seat P/N like an appliance AD would be. So it will be missed on a normal AD search on older airframes.

Dan Thomas

Touchdown! Greaser!

- Joined

- Jun 16, 2008

- Messages

- 11,360

- Display Name

Display name:

Dan Thomas

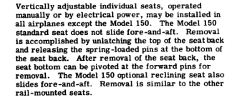

I have electronic copies of both the '53-'62 and '63-'68 100 series manuals. No mention of the seat swap in the earlier manual, and no revision date on the page that would have it. That's the manual that applies to the 172B owned by the OP. In the later manual I see this:Regardless, the easiest route is to find an old revision of the 100 series MM with that statement and change out the seats as a “replacement" using that reference or, use Plan B and treat it as a minor alteration and swap seats.

Now. in both manuals, vertically-adjustable seats are shown as an option, so I take that paragraph above to refer to those seats, not the seats from, say, a 172M. The vertically-adjustable seats in the manuals are steel-tube affairs, one locking pin. Later on the infinitely-adjustable seats were mostly cast aluminum.

There's even an electrically-adjustable seat shown. Did any cars even have that in the early '60s?

I usually followed the minor alteration route when swapping Cessna seats. So in the case of a172M that route would work. Minor route also reduced the heartburn some IAs would get if we used the manual statement as a part replacement.not the seats from, say, a 172M.

Had a great-uncle who collected 40s-50s cars and I recall a number of them had power seats, windows, etc. So I think there were a few at the appropriate price range. And every now and again it was known for a couple of his grand-nephews to go and play with his "fancy" car until his battery was dead.Did any cars even have that in the early '60s?

Last edited: