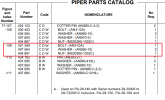

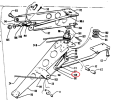

So I took the time to watch the whole video. The Examiner mentions that they did make a point of preflighting the bolt in question. Theirs actually had a cotter pin through it in addition to a nylock so the head had to have popped off the bolt. I believe mine is only a locking nut. As I understand that assembly, there's a bronze bushing inside the eye on the rod, and then the bolt actually pinches another bronze bushing to the stamped link, and the only moving surface SHOULD be the the two bronze bushings nested inside each other. The most likely scenario I think is that the bolt got loose and was spinning in the link, and he mentioned (as I understood it, the audio was pretty poor) that they did a visual check but didn't try to turn it. Probably is worth replacing those bolts once in a while as they're both critical and relatively cheap, as well as touching/trying to twist it during preflight. Good to know about, and hopefully someone can capture a better quality version of the speech at some point.... Too bad there's no good youtubers in Texas

. Seriously I hope

@Daniel Millican would consider having him on.

. Seriously I hope

. Seriously I hope